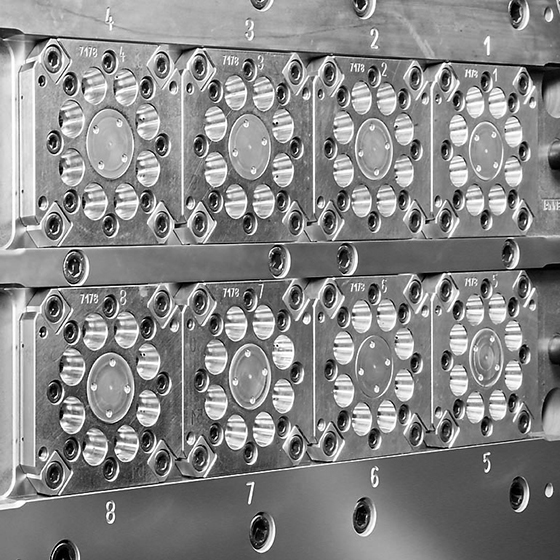

4/6/8-Series Modules

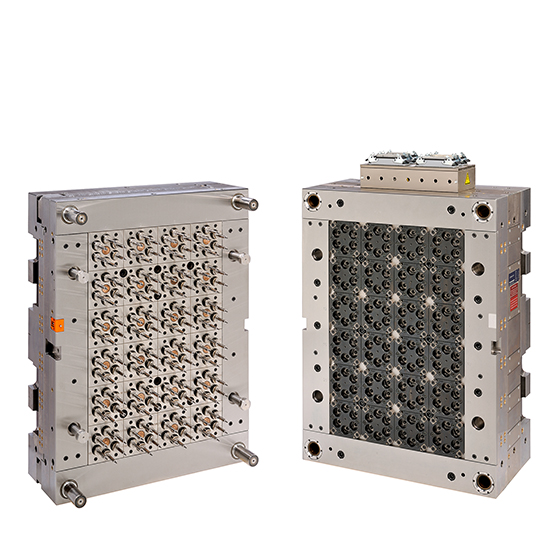

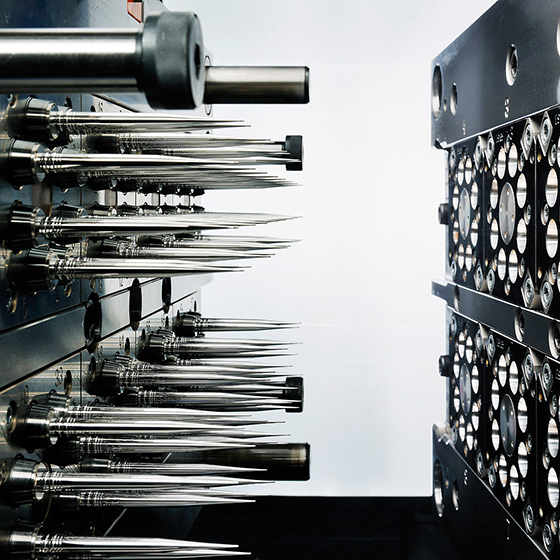

Mold properties Very compact, sophisticated mold concepts featuring the seamless integration of the leak-proof Tanner hot runner technology with edge-gating.

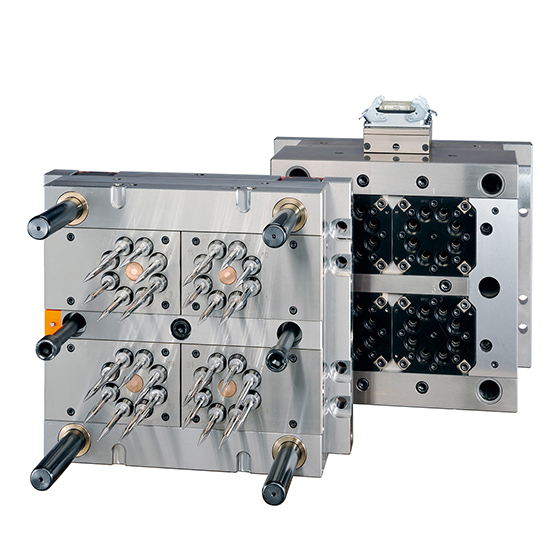

Mold design The modular mold design provides optimal access for time-saving maintenance.

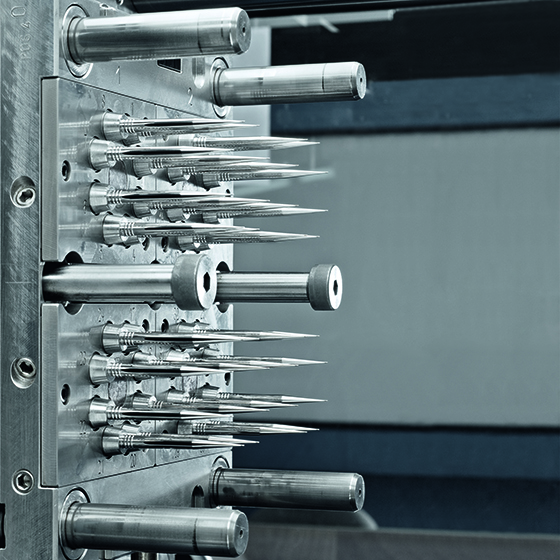

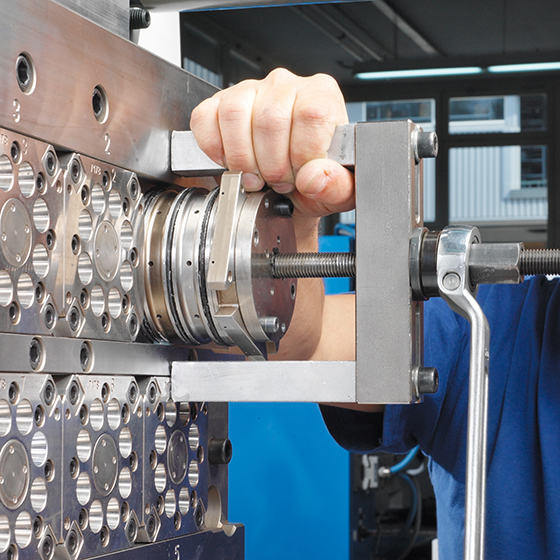

Mold inserts The individual cavity modules, complete with integrated gate components, can be installed or removed from the parting line. Within these, the mold inserts and worn parts can also be quickly and easily replaced.

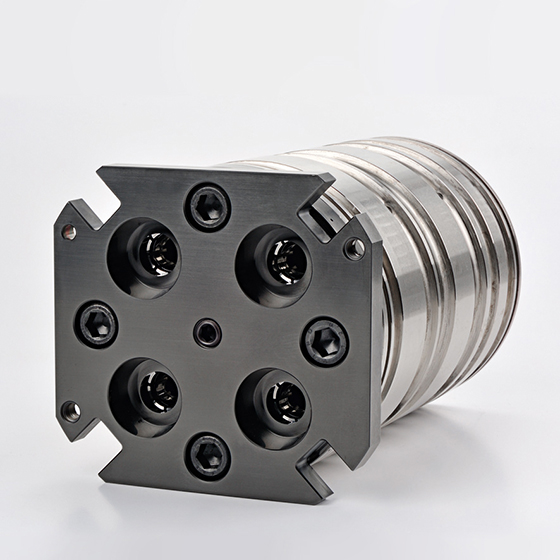

Direct cooling The modular design of our molds enables an optimal cooling circuitry. The efficient and even thermal control of the mold inserts ensures short cycle times and the production of dimensionally stable molded parts.

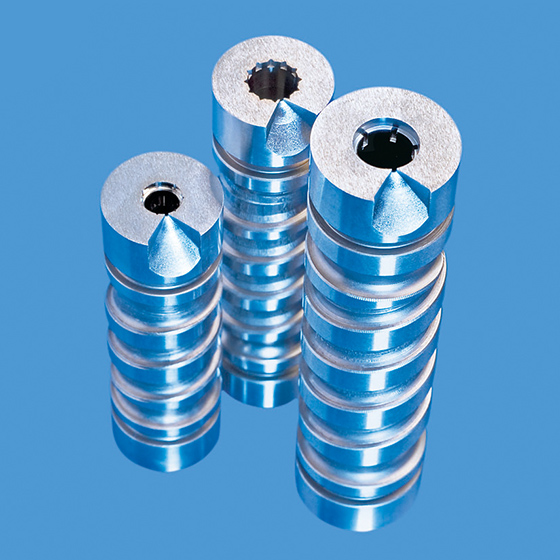

Individual alignment Individually aligned mold inserts guarantee the highest degree of product concentricity and long mold service lives.

Fine-tuning A further technological feature is the precision adjustment of the individual forming inserts to maintain narrow mold tolerances.

Special mold properties Compact, rigid structure with an excellent thermal array and the seamless integration of the leak-proof Tanner hot runner technology with edge-gating.

Modular concept Tanner offers a high degree of conceptual freedom when it comes to the integration of customized product designs into our mold concepts. Ideally suited for family mold applications.

State-of-the-art technology Components optimized down to the smallest detail, together with the use of high-grade steels enable us to produce high-performance injection molds.

Maintenance Easy accessibility to injection components and smart designs minimize production downtimes. Hot runner system components that can be easily replaced for easy maintenance.

Experience Decades of experience and the continuous development of our products guarantee high quality and functional reliability.

Images

To Case Study